Vortek

Vorcone

VorTek Instruments' VorCone® flow meters combine vortex and differential pressure technologies into a hybrid system that measures fluid density, volumetric flow, and mass flow without requiring external density inputs. This design enables accurate monitoring of varying gas compositions, such as natural gas, and provides reliable steam quality (dryness) measurements in saturated steam applications. Additionally, the VorCone meters offer energy monitoring capabilities and advanced diagnostics through DP Health Check™ software, ensuring performance verification and output accuracy.

TurboPro Turbine Flow Meter

VorTek Instruments' TurboPro® Model Pro-T® is an insertion-style turbine flow meter engineered for accurate measurement of liquids, gases, and steam across diverse industrial applications. It employs a rotating turbine blade to detect flow velocity, with each blade's movement generating a magnetic pulse that is measured by an electrical pickup. This local fluid velocity is used, along with parameters such as pipe size and Reynolds Number, to calculate the average fluid velocity and, consequently, the volumetric flow rate. With optional integrated temperature and pressure sensors, the Pro-T® can provide compensated mass flow readings and energy (BTU) monitoring, delivering up to three analog 4–20 mA outputs for variables like volumetric flow rate, mass flow rate, pressure, temperature, and density. Its hot-tappable insertion design allows for installation without process shutdown, and it offers high accuracy with rangeability up to 17:1, handling temperatures from -450°F to 850°F and pressures up to 1500 psig.

Pro-V Vortex Flow Meter

VorTek Instruments' Pro-V® vortex flow meters utilize the von Kármán effect to measure flow by detecting the frequency of vortices shed from a bluff body, with the frequency directly proportional to the flow velocity. Their multivariable design integrates a vortex velocity sensor, RTD temperature sensor, and solid-state pressure transducer, enabling accurate measurement of volumetric and mass flow, temperature, pressure, density, and energy (BTU) from a single device. Available in inline (Model M24) and insertion (Model M23) configurations, these meters are suitable for various applications, including liquids, gases, and steam, and offer high accuracy with rangeability up to 100:1, operating temperatures up to 750°F (400°C), and pressures up to 1500 psig .

Ultrasonic Flow Meters

Vortec Instruments Ultrasonic Flow Meters provide accurate and reliable measurement of liquid flow without any moving parts. Using advanced ultrasonic technology, they deliver precise readings with minimal maintenance and are ideal for a wide range of industrial and commercial applications.

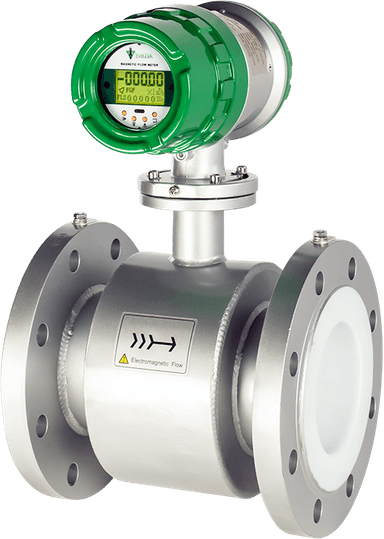

Electromagnetic Flow Meters

The Pro‑M Series Electromagnetic Flow Meter delivers accurate, maintenance‑free volumetric flow measurement of conductive liquids using Faraday’s law of electromagnetic induction. With no moving parts and full‑bore design, it provides zero pressure loss and stability unaffected by fluid temperature, pressure, density, viscosity, or particulates. Available in pipe sizes from ½ inch to 80 inches and offering up to ±0.2 % accuracy, it supports advanced communications such as Modbus RTU and HART and includes an energy‑metering option when paired with an external temperature sensor

FlowCalc™ Computer

The Vortek FlowCalc Computer is a field mounted multivariable flow computer designed for accurate liquid and gas measurement in custody or non custody applications. It features advanced diagnostics including the DP Health Check system for continuous monitoring of differential pressure meter health. Modular configurations and flexible communications such as HART, Modbus, BACnet, and PoE make it easy to integrate into automation systems while reducing lifecycle costs.